PRODUCT

Products

GN-PAD

What is the GN PAD?

Purpose of development

- There the sliding issue during process equipment handling the product is keep occurring on the production which are semi-conductor industry, LCD Flat panel industry, OLED industry.

(100% solved issues which are sticky, slip, holding marking issue)

(Contains no product broken and mis-alignment issue)

Where the GN PAD comes from.

- It’s created in mimicry of nature to get the slip resistance function.

What the strong point a GN PAD is.

- No slip & sticky issues for the plat products on the handling equipment. (Available to speed-up of the handling unit)

- No-holding marks on the surface of product. (Vacuum, O-ring and etc.. : Unnecessary the cleaning process and equipment for the holding marks)

- No needs the utilities which are an electrical or air supplying device. : Save Cost)

- Easy and simple cleaning. (within 30seconds per 1 pad)

- No-Outgassing, No chemical reaction.

The application of principal : van der Waals forces

Theory of Van der Waals

In molecular physics, the van der Waals forces, named after Dutch scientist Johannes Diderik van der Waals, are distance-dependent interactions between atoms or molecules. Unlike ionic or covalent bonds, these attractions are not a result of any chemical electronic bond, and they are comparatively weak and more susceptible to being perturbed. Van der Waals forces quickly vanish at longer distances between interacting molecules.

Van der Waals forces play a fundamental role in fields as diverse as supramolecular chemistry, structural biology, polymer science, nanotechnology, surface science, and condensed matter physics. Van der Waals forces also define many properties of organic compounds and molecular solids, including their solubility in polar and non-polar media.

If no other forces are present, the point at which the force becomes repulsive rather than attractive as two atoms near one another is called the van der Waals contact distance. This results from the electron clouds of two atoms unfavorably coming into contact. It can be shown that van der Waals forces are of the same origin as that of the Casimir effect, arising from quantum interactions with the zero-point field. The resulting van der Waals forces can be attractive or repulsive.

The term "Van der Waals forces" is also sometimes used loosely as a synonym for the totality of intermolecular forces. The term always includes the force between instantaneously induced dipoles (London dispersion force), sometimes includes the force between a permanent dipole and a corresponding induced dipole (Debye force), and – less frequently – includes the force between permanent dipoles (Keesom force).

Contents.

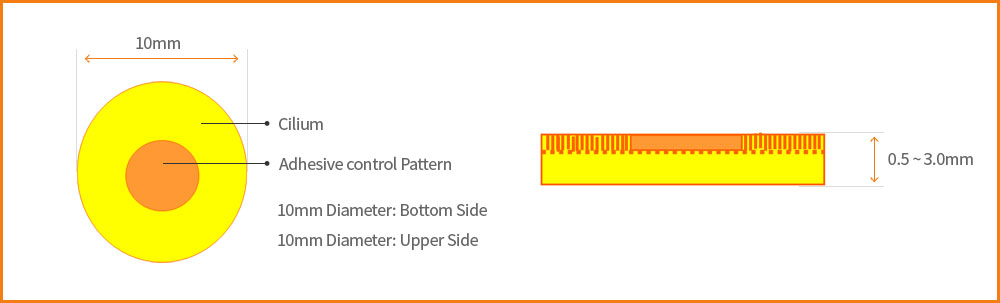

Basic Field specification of the GN PAD

| Performance | Requested Specification | Solution |

|---|---|---|

| Clean room moving device |

300mm Prime Wafer (Polished Back side), THK 775 um, Weight 129g |

Tested by standard specification of pad (1mmm THK x 10mm D) (Depends on the handling products) |

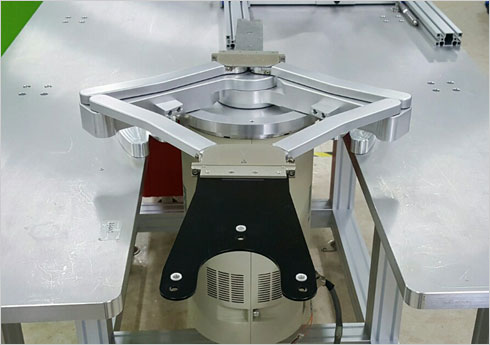

| Wafer Holding performance | Acceleration of horizontality : Tested till10,000mm/sec (No Miss alignment) |

Horizontal adhesion force(Friction): 1.3N/cm2 (1Point) 5.3 N/cm2 (3Point) (It’s available to control the holding performance) |

| Placement | Vertical speed: Placed at 500 mm/sec (No Miss alignment) | Vertical adhesion force :1.7N=< (It’s available to control the holding performance) |

| Responsibility |

Keep the pad’s performance above 99% after 150,000 cycle (200 cycle/hr)*(24 hr)*(365 days) |

On the marathon test at actual moving environment. |

| Contamination |

Particle free (None particle material source), Cleaning SOP when the particle incoming. |

Simple cleaning method (IPA or N2 Blower), Anti-chemical (Ex: IPA, Acetone etc..: up to 48hrs soaked test) |

| Using environment | Clean room class <1000 , ~250˚C | Tested on high temp(270℃) up to 5hrs. |

Basic Field specification of the GN-PAD

| Standard | Changeable spec. | |

|---|---|---|

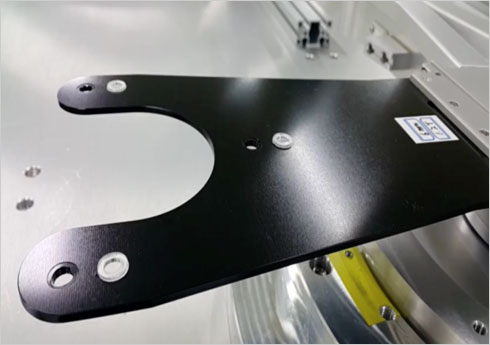

| Thickness | 1.0 mm THK | 0.2mm ~ 5.0mm < |

| Diameter | 10mm Ø | 3mm Ø ~35mmØ (Available to change the shape into Square) |

| Holding performance |

Horizontal Adhesion force: 1.3 N/㎡ (Per pad) Vertical adhesion force: 1.7 N/㎡ (Per pad) |

0.8 N/㎡ ~6.5N/㎡ (Horizontal) (Available to handle the 300mm Wafer to 90 to 180 degree) |

| Using PAD’s Q’ty | 3 Pads on the EFEM (Based on 300mm wafer) |

Depends on customer requirement (Mixable to use with Vacuum device) |

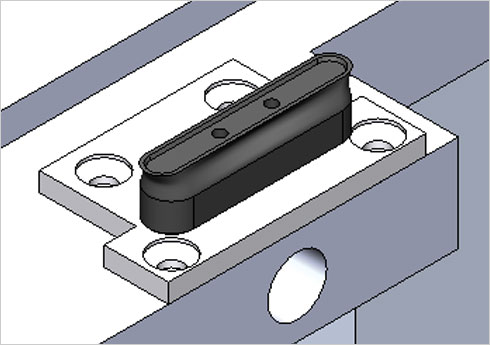

| Installation of the PADs | Molded on the EFEM | Screw (Installed the nuts in pad) or Adhesive tape (for clean room) |

| Warranty | 1 year guaranty (Free charge to change If it damaged within 1 year) |

- GN PAD is particle free material and very strong for the chemical reaction from the process .

GN-PAD’s comparison for end-user

| Weakness of current PAD | Strong point of GN-PAD |

|---|---|

|

Urethane PAD (Composited Rubber) : Weak for high temp, chemical and Slipping issue during transportation of product |

100% clear the slipping issue and strong for high temp, chemical issue |

|

PEEK PAD (Super engineering plastic) : Slipping issue occurs and make some scratch during transportation of product when slipped |

100% clear the slipping issue and no scratch issue |

|

Vacuum PAD (High vacuum PAD) : Residue issue on surface of product(holding Mark) (Maintaining cost for utility and replacement) |

No residue issue on surface of product. (No maintaining cost during warranty) |

|

Viton (Composited rubber for anti chemical ) : Weak for high temp and residue issue |

Anti-chemical and high temp with no residue(Vacuum Chamber 300℃, 260℃ in stand-by) |

|

FKEM (Composited Fluor rubber) : Weak for high-temp and residue issue |

Strong for chemical and high temp, No out-gassing issue |

|

EFEM of Pocket design(Re-designed EFEM for current issues which are happened on current pad) :Chipping issue of product and low speed of robot |

No chipping and broken issue and keep the high speed of the robot |

|

EFEM of Gripper design (Re-designed EFEM for current issue and added device: Electronic solenoid) : Chipping and Broken issue. |

No chinpping and broken issue |

| Weakness of current PAD |

|---|

|

Urethane PAD (Composited Rubber) : Weak for high temp, chemical and Slipping issue during transportation of product |

|

PEEK PAD (Super engineering plastic) : Slipping issue occurs and make some scratch during transportation of product when slipped |

|

Vacuum PAD (High vacuum PAD) : Residue issue on surface of product(holding Mark) (Maintaining cost for utility and replacement) |

|

Viton (Composited rubber for anti chemical ) : Weak for high temp and residue issue |

|

FKEM (Composited Fluor rubber) : Weak for high-temp and residue issue |

|

EFEM of Pocket design(Re-designed EFEM for current issues which are happened on current pad) :Chipping issue of product and low speed of robot |

|

EFEM of Gripper design (Re-designed EFEM for current issue and added device: Electronic solenoid) : Chipping and Broken issue. |

| Strong point of GN-PAD |

|---|

| 100% clear the slipping issue and strong for high temp, chemical issue |

| 100% clear the slipping issue and no scratch issue |

| No residue issue on surface of product. (No maintaining cost during warranty) |

| Anti-chemical and high temp with no residue(Vacuum Chamber 300℃, 260℃ in stand-by) |

| Strong for chemical and high temp, No out-gassing issue |

| No chipping and broken issue and keep the high speed of the robot |

| No chinpping and broken issue |

GN-PAD for improvement of production

| Present device |

Cost Save

|

GN-PAD |

|---|---|---|

|

Cost for Utility : Vacuum pump, supplying utilities |

No Utility cost | |

|

Cost for individual device (Purchase, installation) : Vacuum ejector, Solenoid and etc.. |

No device cost | |

|

Cost for maintenance : Labor cost for maintenance |

No maintenance coast during warranty |

| Present device |

|---|

|

Cost for Utility : Vacuum pump, supplying utilities |

|

Cost for individual device (Purchase, installation) : Vacuum ejector, Solenoid and etc.. |

|

Cost for maintenance : Labor cost for maintenance |

|

Cost Save

|

| GN-PAD |

| No Utility cost |

| No device cost |

| No maintenance coast during warranty |

| Improvement of Process |

Improvement of Process

|

GN-PAD |

|---|---|---|

| Decrease the thru-put of transportation by current issues | Increase the thru-put of transportation (max speed) by cleared current issues | |

| Decrease the thur-put and capability by additional cleaning process for residue | No additional cleaning process by residue. | |

| Low capability by alignment issue of product | Improve the capability of production by clear the alignment of product |

| Improvement of Process |

|---|

| Decrease the thru-put of transportation by current issues |

| Decrease the thur-put and capability by additional cleaning process for residue |

| Low capability by alignment issue of product |

|

Improvement of Process

|

| GN-PAD |

| Increase the thru-put of transportation (max speed) by cleared current issues |

| No additional cleaning process by residue. |

| Improve the capability of production by clear the alignment of product |

Comparison table (GN PAD and Others)

| Comparison Table for GN PAD and Others | ||||||

|---|---|---|---|---|---|---|

| Issues (symptom) | Products | O-rings | Edge Grip | Urethan PAD | Vcc PAD | GN-PAD |

| #1 Slip Issue | Semiconductor(4' ~12'), FPD, Glass, OLED | O | X | O | X | X |

| #2 Brocken Issue | Semiconductor(4' ~12'), FPD, Glass, OLED | X | O | X | X | X |

| #3 Holding Marks | Semiconductor(4' ~12'), FPD, Glass, OLED | O | X | O | O | X |

| #4 Maintenance Issue | Semiconductor(4' ~12'), FPD, Glass, OLED | X | X | X | O | X |

| #5 Replacement Issue | Semiconductor(4' ~12'), FPD, Glass, OLED | O | X | O | O | X |

| #6 Installation Issue | Semiconductor(4' ~12'), FPD, Glass, OLED | X | X | X | O | X |

| #7 Cleaning Issue | Semiconductor(4' ~12'), FPD, Glass, OLED | O | X | O | O | X |

- Comments:

- Brocken Issue : If there are slip issues occurred on O-rings, Urethan PAD, Vcc PAD and then the bocken issus are follows. (Except the GN PAD)

- Holding Marks :It should be possible to skip the cleaning process but some of production has to do clean a product up for particles or holding marks. (The GN PAD is unnecessary)

- Maintenance Issue : If other units needs to replacement period, P.M period or utility maintenance(Mechanical device, electronic device) and then maintenance engineer should be involve for this. (The GN PAD is unnecessary)

- Replacement Issue : If other units needs to replacement period and then the process should be shut it down with engineer for this. (The GN PAD is unnecessary)

- Installation Issue : It will takes the time less than 10 minutes for the GN PAD installation. (Based on 3 pads)

- Cleaning Issue : It will takes the time less than 1 minutes for the GN PAD cleaning(Based on 3 pads), if it is necessary but it shouldn't be no needs for the GN PAD in clean-room environment.

- No additional budget for a man power (Maintenance, P.M, Replacement).

- No additional budget for the utilities. (Electronics, mechanical units: vacuum pump, suppling line)

- No down time for the P.M, replacement, maintenance

- No additional budget for the replacement of unit. (replacement time period for 1 year)

- Short-time cleaning (Unnecessary for the GN PAD if it’s using in clean room environment)

- Short-time Installation & replacement

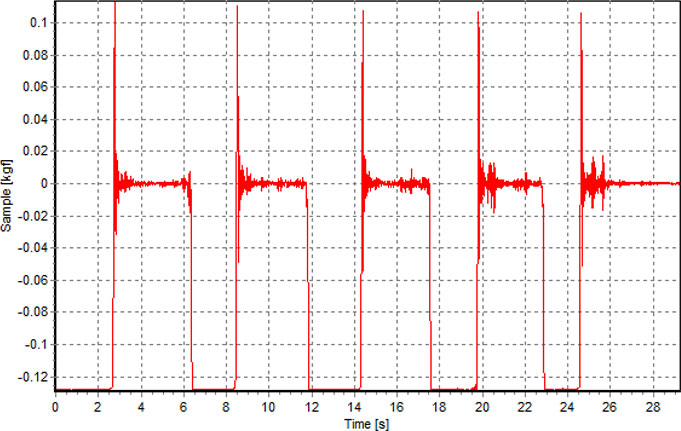

Test for adhesion force

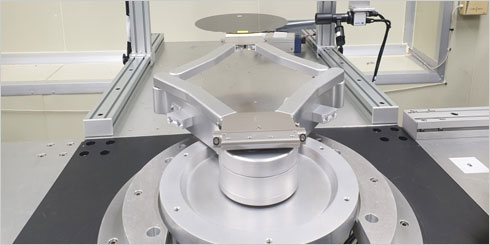

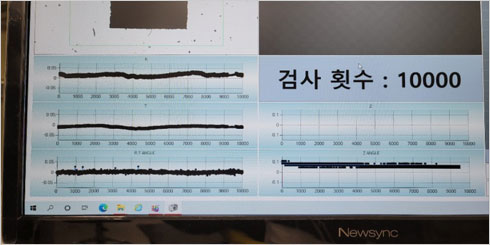

Marathon test > New inquiry: 5,000~10,000 cycles marathon Test before shipping

- Vacuum Pad strength(horizontal): 450mmHG = 6 N/cm2

(Available specification in GN-PAD: Not requested for wafer product , The requested specification should be different from end-users) - Adhesive strength per GN PAD(Vertical direction): 1.78N (1.0cm diameter)

- Installed 3 pads on the blade: 5.34N( Horizontal direction and friction:Same pad q’ty with vacuum or edge gripper)

Test and analysis for vertical direction (Placement of product)

Result of vertical test (Placement of wafer)

-

-

- Preload: 130g (300mmWafer)

- Retraction speed: 50mm/s

- Tested adhesion force: 1.37 N (Based on 3 PADs, 1 Set )

- Size of pad: 1.0 cm2 (10mm x D. Standard pad)

- Horizontal adhesion force(Friction force): 5.41 N/cm2

- Available to change the each adhesion force

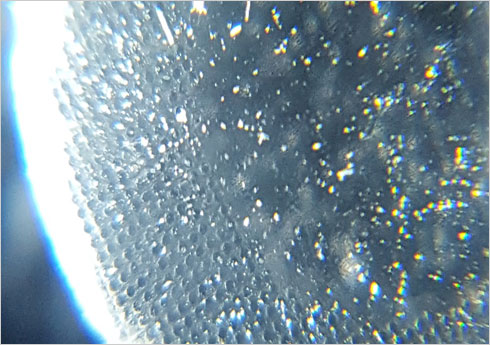

High temperature Test

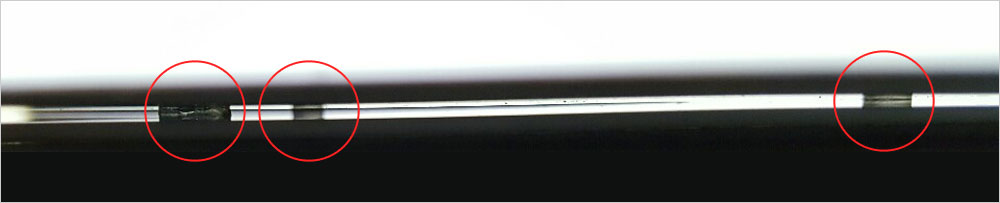

-

Before ( about x 100)

-

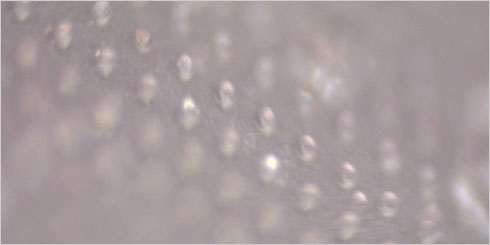

After (about x 100)

- Spec of used Pad: Diameter > 10mm, THK > 1mm

- Test method: Standard prime 300mm wafer on EFEM

- Maximum temperature : ~280°

- Results : Nothing to changed (Adhesion force, Shape, Out-ward)

- Tested time: 5 Hrs

ESD Pad (Electro Static Discharge)

Development Purpose

- Electto-Static discharge technology is very

Important for High precision manufacturer such as FPD and Semiconductor. - Electrostatic is occurring only contact to any environment condition.

- And it gives a serious defect to FPD and Semiconductor.

- So it must be discharged or not exist on the products.

Application

- FPD manufacturing line : FPD panel line conveyer, Film remove, trans robot.

- Semiconductor : Si-wafer transport, Robot arm, sputtering,

- Sensitive process for ESD.

Feature.

- Possible to design at each customer manufacturing line. (customize)

- Adhesive force control (same as General GN-PAD)

- High heat resistance.

- ESD : Ω 10^6 ~ 10^10

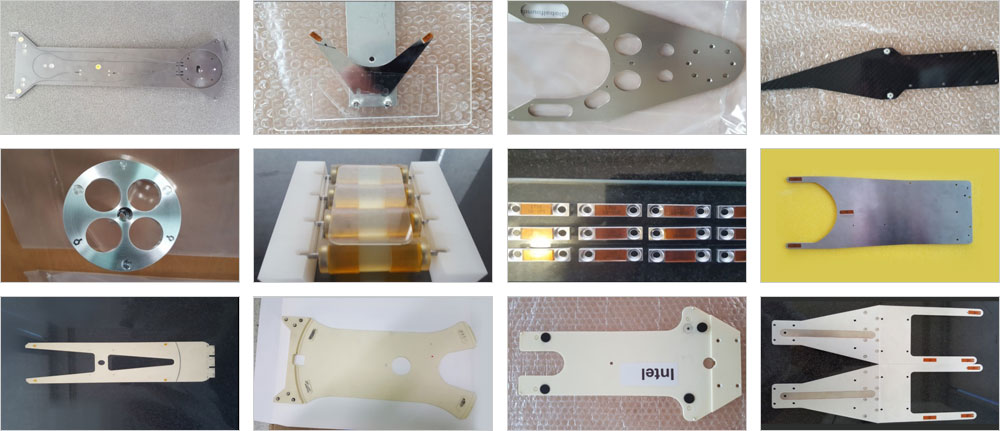

ESD GN-PAD

-

Semi-conductor

(Insert Type)

-

Semi-conductor

(Adhesion tape Type)

-

FPD

(Screw Type)

-

Measurement of Resistance

- * Specifications of ESD GN-PAD

- Specification of resistance ) 10^6 ~ 10^9 Ω

- Adjustable range of the Resistance : 10^5 ~ 10^11 Ω

- Contact and Conductivity– Excepts the coated or Anodized on the handling device

- Semiconductor (Insert type) : Contact the end-effector, directly

- Semiconductor (Adhesion tape type) Contact the end-effector, directly with adhesion tape

- FPD (Screw type) Direct contact or contact by base plate (Aluminum plate, Carbon peek and etc..)

- * Electric resistance of aluminum plate: 10^3 Ω

- Adjustment and control of the adhesion force:

All of the required shape and adhesion are adjustble as much as regular GN-PAD

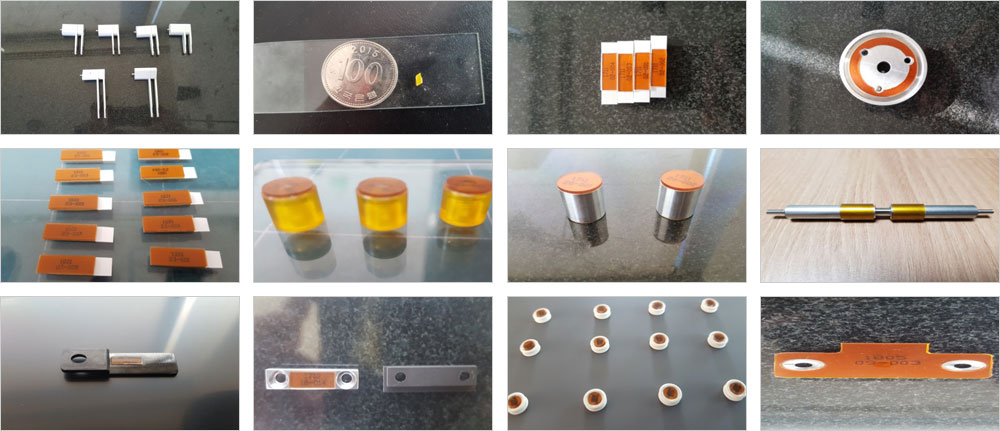

Basic Out-ward (Fixable to thickness and Size)

-

Cilium

-

Picture for Pad types

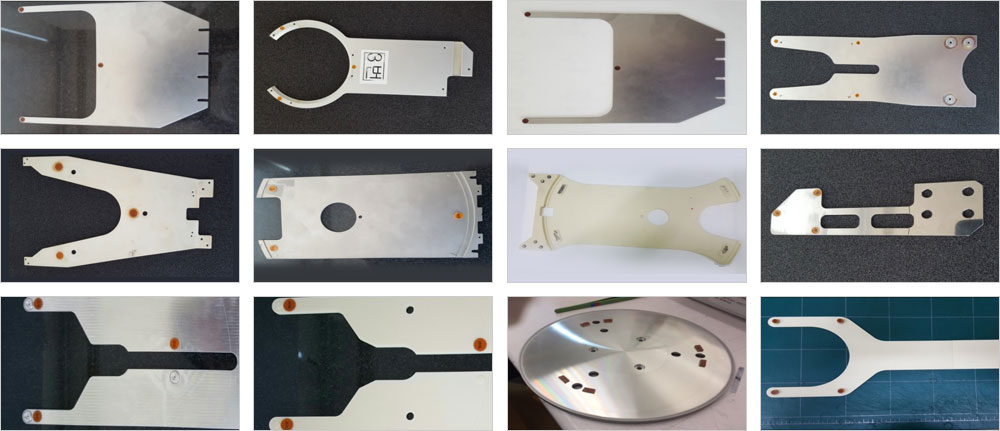

Installed Images( For 300mm Wafer)

Installed GN-PAD (Actual working In customer site)

Installed GN-PAD (Actual working in customer site)

Installed GN-PAD (Actual working in customer site)

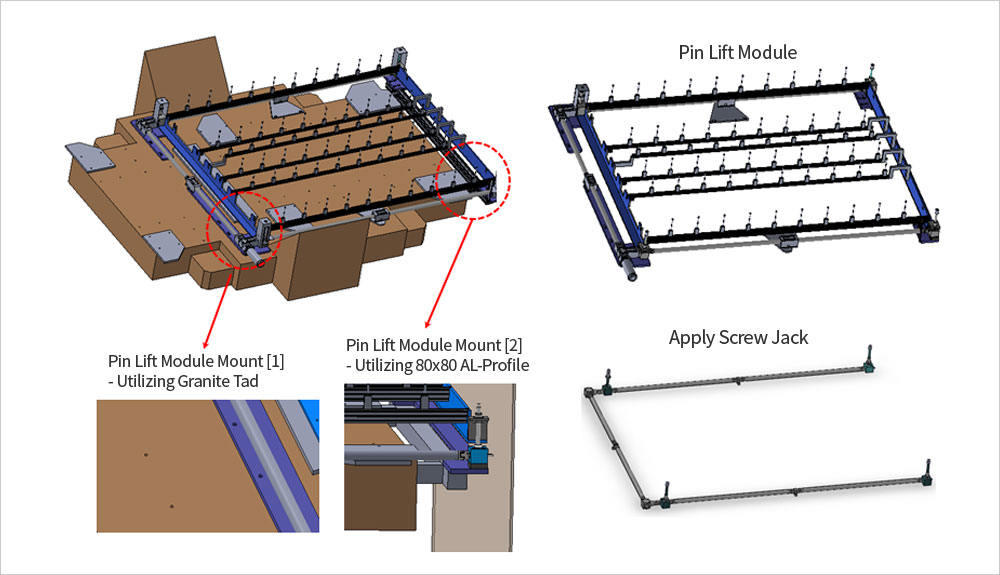

Glass Lift Pin

-

PAD’s location (Actual example)

- Requested the Anti-static pad from some of end-users.

(Completed the Anti-static pad and only remains the installation method)

Glass Flip process (180 degree turn)

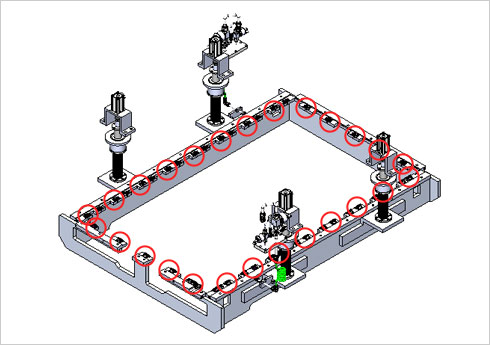

PAD’s location (Total: 32EA pads installed as viton)

- Depends on process and specification of product.

(Current issue: Residue issue occurs by Vacuum pads and broken issue

KOR

KOR ENG

ENG